Presentando LF1390 – Macchina taglio laser

Le macchine per taglio laser LF1390 sono di dimensioni compatte con gantry in alluminio aeronautico di 3a generazione. È fabbricato con standard aerospaziali e prodotto da 4300 tonnellate di estrusione per pressa. Il suo gantry non ha un foro di sabbia e può raggiungere 66061 T6, la forza più forte.

Le macchine hanno un design Dual Rain e Dual Driver e, su entrambi i lati, l’asse Y è dotato di due guide e due viti a ricircolo di sfere, per garantire la linearità e il grado di arco quando è in funzione il taglio ad alta velocità.

LF1390 può mettere a fuoco automaticamente senza operazione manuale. Il software regola automaticamente la lente di messa a fuoco per realizzare fori automatici di perforazione e taglio di diverso spessore. La velocità della lente di messa a fuoco automatica che regola automaticamente è dieci volte quella di un obiettivo di regolazione manuale.

Le macchine per il taglio laser hanno un ampio campo di regolazione: 10 mm ~ + 10 mm, precisione 0,01 mm, adatto per 0 ~ 20 mm, diversi tipi di piastre e una lunga durata. Sia la lente del collimetro che la lente di messa a fuoco hanno un dissipatore di calore ad acqua che migliora la vita delle macchine riducendo la temperatura della testa di taglio.

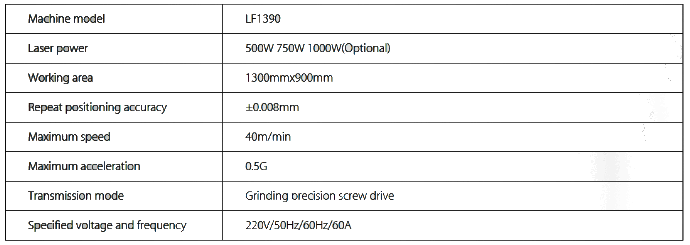

La trasmissione LF1390 è dotata di servomotore Panasonic giapponese, vite a ricircolo di sfere TBI dual driver importata per Y e X e guida di guida Hiwin, la precisione di posizionamento dello strumento macchina può essere 0,008 mm e l’accelerazione di taglio è 0,5 G tutte le caratteristiche che garantiscono precisione. La vita lavorativa delle macchine è di oltre 10 anni.

Dai un’occhiata ai Parametri Tecnici