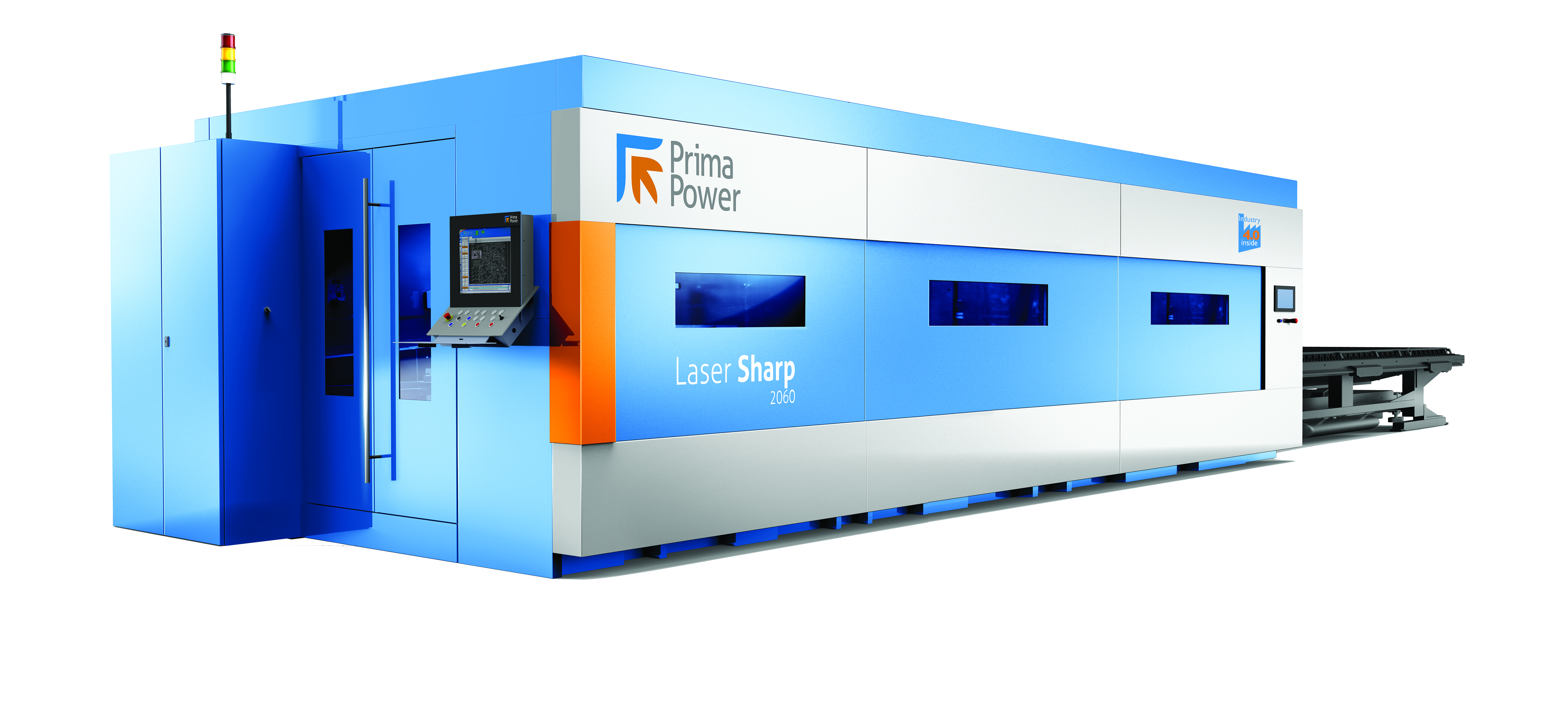

Laser Sharp 2060

La nuova macchina laser di grande taglia di

Prima Power adatta ad applicazioni heavy duty

- Laser sharp 2060 e l’ultima arrivata nella famiglia di macchine laser 2D Prima Power.E’ una macchina laser fibra di grande taglia per la lavorazione di lamiere medie e grandi. Forte, affidabile e precisa, è un cavallo di battaglia per le moderne officine.

- Sharp (affilato) per definizione, con le sue grandi dimensioni, la costruzione robusta e l’elevata potenza laser disponisbile, questo prodotto è adatto per una vasta gamma di settori pesanti come i settori agricolo e movimento terra, le industrie pesanti e i veicoli commerciali.

- Laser Sharp combina elevata produttività, anche grazie al tempo di piercing migliore della categoria, con alta efficienza e bassa manutenzione, garantendo un eccellente rapporto qualità-prezzo

Il software include un sistema informativo con spiegazioni del codice di allarme, manuali utente, coda di lavoro dinamica e funzioni di trasferimento rapido dei file. Tutto ciò consente di supportare l’operatore in vari modi agevolando e promuovendo l’autoapprendimento, fornendo istruzioni per le operazioni di recupero e un facile accesso a manuali elettronici, manuali dei pezzi di ricambio e così via.Un database tecnologico è memorizzato sul computer CNC fornendo un gran numero di parametri di taglio per diversi tipi di materiali. Per ottimizzare rapidamente i parametri per materiali nuovi o diversi, i parametri di taglio laser possono essere modificati direttamente nel database. L’operatore può anche personalizzare i parametri di taglio online, direttamente dal pannello touchscreen, mentre è in corso il taglio laser (ad es. Velocità di avanzamento, riduzione della pressione del gas e così via).

Caratteristiche principali:

- Integrazione totale con il generatore laser

- Controllo numerico, integrato con la macchina, basato su PC standard

- Programmazione XML

- Touchscreen LCD da 19 “

- Servoazionamenti Prima Power

- Funzioni avanzate di riavvio automatico e manuale

- Funzioni avanzate di riavvio automatico e manuale

- Funzioni di modifica, anteprima e traccia

- Controllo ottico di precisione (OPC) per la diagnostica della centratura dell’obiettivo

- Sistema di riferimento automatico per l’aggiornamento rapido del programma con la posizione reale del foglio sulla macchina

- Manuale d’uso, programmazione e manutenzione online con diagnostica intuitiva

- Possibilità di creare, eseguire e modificare elenchi di lavori per operazioni senza pilota

- Connessione TELESERVICE al servizio clienti Prima Power

- È possibile inviare messaggi di posta elettronica per notificare la manutenzione periodica scaduta o guasti della macchina.

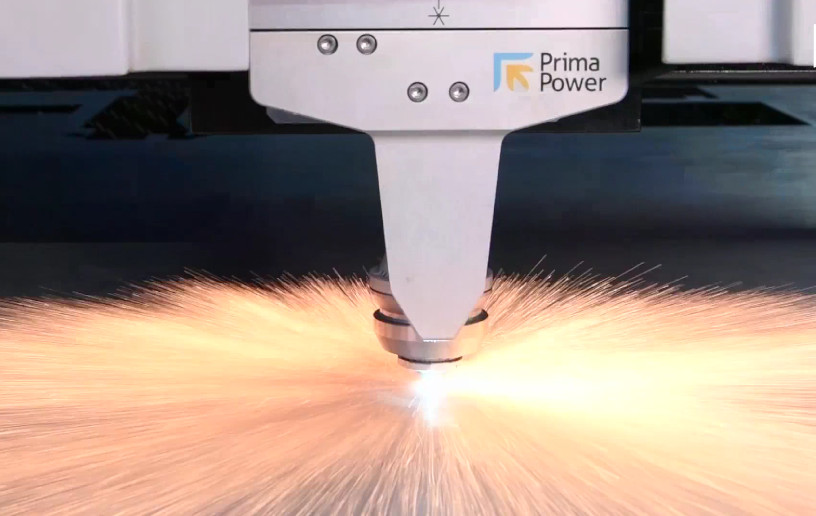

Sistema autofocus della testa di taglio e del fascio di taglio

Prima Power ha sviluppato la sua nuova testa di taglio in fibra con ottica adattiva per la gestione automatica della posizione focale e del diametro e una misurazione stand-off rapida, reattiva e accurata.

La nuova testa è progettata per un’eccellente qualità di taglio e dinamica su tutti i materiali, le massime pressioni di taglio (struttura meccanica certificata) e l’ambiente più difficile (custodia completamente sigillata e protetta).

La testa è dotata di un unico obiettivo di messa a fuoco, adatto a tutte le esigenze di produzione. Il vetro protettivo è integrato nel cassetto dedicato, per un’ispezione più semplice.

Controllando la regolazione della posizione e del diametro della messa a fuoco, la flessibilità nel taglio di vari spessori della lamiera senza intervento manuale garantisce la massima produttività nella produzione. La posizione di messa a fuoco cambia spostando gli obiettivi di collimazione, mentre il diametro di messa a fuoco può essere modificato variando la lunghezza focale della collimazione in modo indipendente.

La centratura dell’obiettivo viene controllata automaticamente dalla funzione Optical Precision Control (OPC) come e quando necessario o quando vengono utilizzati per la prima volta. Le possibili differenze tra la posizione reale e la posizione teorica del fascio focalizzato sono mostrate sull’interfaccia utente grafica del sistema di controllo.

Due manopole rotanti situate nella parte anteriore della testa di taglio possono essere utilizzate per apportare le correzioni necessarie allo spostamento assiale dell’obiettivo di messa a fuoco.

Un sensore capacitivo mantiene una distanza costante tra l’ugello e il foglio.

Il sistema è dotato di un kit di pulizia degli ugelli e di calibrazione del sensore. Dopo aver eseguito un numero predeterminato di fori o parti forate, la macchina esegue automaticamente il ciclo di pulizia degli ugelli e di calibrazione del sensore.

La testa è dotata di un sistema magnetico anticollisione (Safe Impact Protection System – SIPS) che libera la testa dall’asse Z per evitare danni in caso di collisioni con il pezzo.

Sul pannello di distribuzione del gas di taglio standard è presente un selettore a 2 posizioni, più comunemente per azoto e ossigeno, che consente la commutazione automatica tra i due gas

|

Altre charatteristiche

|

Come suggerisce il nome, la nuova macchina è “affilara” per tagliare qualsiasi materiale. La testa fibra di Laser Sharp è progettata e sviluppata da Prima Power per ottenere qualità di taglio e dinamiche ecellenti su tutti i materiali e gli spessori, anche grazie all’ottica adattiva per la gestione automatica della posizione focale e del diametro. La struttura meccanica certificata della testa laser la rende adatta anche alle più elevate pressioni di taglio, mentre la copertura sigillata e protetta resiste agli ambienti più difficili.